AI + Data Modernization That Fits Mid‑Market Manufacturing Budgets

Embedded tiger teams for AI, data, and modernization projects

JetBridge provides embedded engineering tiger teams that modernize data, automate workflows, and ship compliant AI fast—on budget and without adding

permanent headcount.

(not “resume spam”)

1) Who we are

Founder-engineers, not consultants. Our team built Five9 (public SaaS) and DoctorBase (scaled to ~9M U.S. users pre-acquisition). We run delivery like operators: clear scope, tight feedback loops, production-grade quality, and measurable outcomes.

2) Why we're different

Live pair-programming is mandatory. Every engineer is screened in real-time on applied problem-solving and code quality. It's expensive and time-consuming — which is exactly why most vendors don't do it.

3) How we work

University-anchored talent funnels. We partner with administrators and professors in Brazil, Poland, Ukraine, and Colombia to recruit top CS and applied-math talent (including PhD candidates), then train them on production AI/data and enterprise modernization patterns.

Layton Wedgeworth

Current: Anthropic (Former: Invitae, Path, Ebay)

4) Social proof

Teams we've built have delivered systems across Fortune 500 ecosystems (e.g., LabCorp) and tier-1 VC-backed startups (including a16z portfolios).

What you buy

- A small, senior team that plugs into your existing stack.

- Production increments every 1-2 weeks (no “big reveal” delivery).

- Security-by-design: audit trails, access control, and runbooks.

- Clean handoff: documentation, dashboards, and ownership transfer.

Engagement model

Start with a defined 6–10 week pilot (fixed scope, clear metrics). If it works, scale to a phased rollout. If it doesn't, stop—without carrying a permanent cost structure.

Next steps

Free 45-minute consult with an AI architect: proposed architecture + pilot scope + staffing plan + budget range.

Note: projected ROI depends on data quality, integration access, adoption, and vendor constraints. We validate assumptions in discovery and lock the pilot scorecard before build.

Case Study: Plant Data Spine + Reliability Automation

Project context

| Client | Specialty manufacturer • 4 plants • 312 production assets • ERP + MES + historian mix |

| Starting point | Reactive maintenance, quality escapes, spreadsheet planning, siloed plant data, limited real-time visibility. |

| Goal | Reduce downtime + scrap by integrating plant data and deploying predictive + quality automation without disrupting MES. |

Constraints we designed for

- OT/IT boundaries: minimal disruption; secure data bridges; strict change windows.

- Inconsistent asset IDs and hierarchies across plants.

- Near-real-time alerting for critical assets.

- Segmented networks with strong audit requirements for changes.

What we shipped (8-week pilot → 6.0-month rollout)

Manufacturing data spine

- MES/ERP/historian ingestion

- Standardized asset taxonomy

- Plant KPI dashboards

Reliability + quality automation

- Failure risk scoring + work orders

- Defect detection (where applicable)

- Root-cause toolkits

Secure operations

- RBAC + audit logs

- Alerting + runbooks

- CI/CD for models + configs

ROI snapshot (measured impact + financial model)

| Financial Line Item | Value |

|---|---|

| Tiger team cost (pilot + rollout) | $968,210 |

| Annualized run-rate savings | $2,784,930 |

| Annualized run-rate revenue lift | $1,126,440 |

| 12-month net benefit | $2,943,160 |

| Payback period | 15.8 weeks |

| 12-month ROI | 304.0% |

Method: hard-dollar savings are anchored to labor minutes, throughput, leakage capture, and vendor spend. Revenue lift reflects conversion, cycle time, and retention improvements attributable to the shipped workflows.

Appendix A:

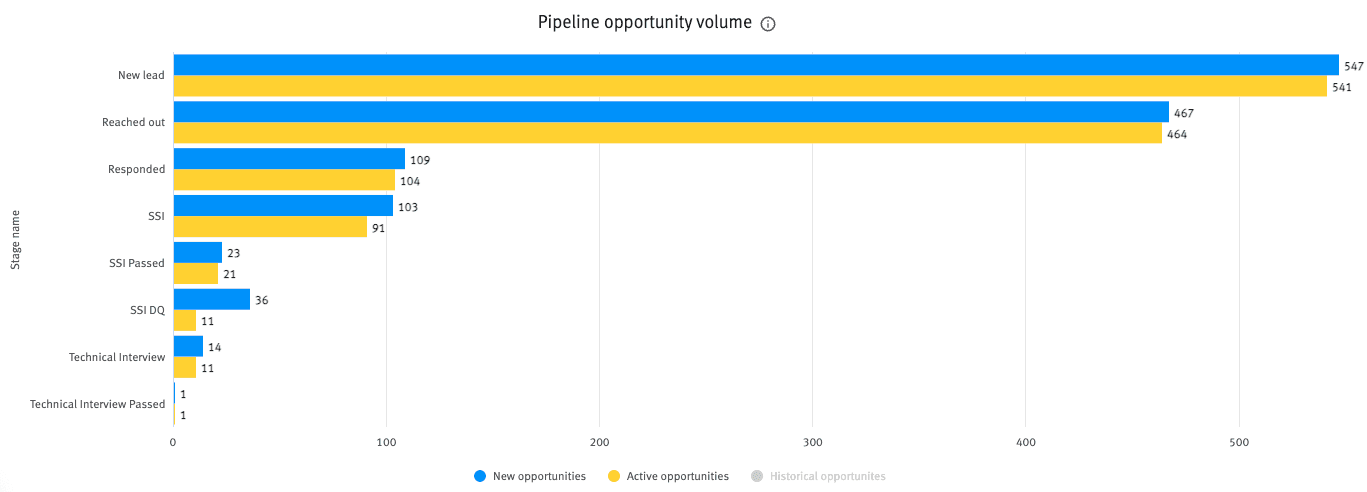

Hiring just one fullstack engineer (senior) requires over 500 candidates sourced, 100 initial interviews, and 14 two hour technical live pair programming to have one candidate pass our test.

Nobody else in our industry does this rigor.